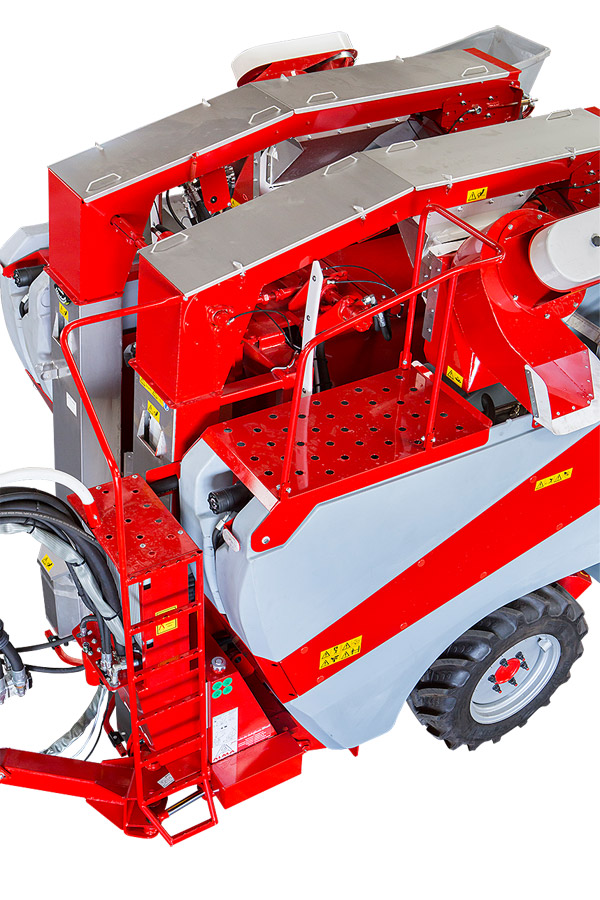

Sélecta 3, powerful, fast, practical and durable

The new generation of SELECTA 3 machines.5 different grape sorting options.Whatever you need, a solution is right at hand!

The SÃĐlecta 3 is the practical and reliable solution for grape harvesting in consideration of the whole grape tree.

Simple and economical, the SÃĐlecta 3 guarantees low maintenance. All daily maintenance work can be carried out quickly and without much exertion.

There is no risk of downtime during the season. Moreover to optimise your yield, it gently gathers at high performance.

Its great speed and high performance are equal to that of self-driven harvesters.

The SÃĐlecta 3 adapts to all vineyards....Possibility to elevate the machine to 700 mm for steep inclinations.Wheel motors ( 250 et 400 bars ) for steep slopes.

Easy to clean : guaranteed hygiene !

The upper shutters open, the hatches in the front are wide for optimal cleaning.

The collection tunnel is completely closed, the structure is designed to protect the harvester head.

its well-engineered frame

Reducing movements to 3.50 m at the row end.

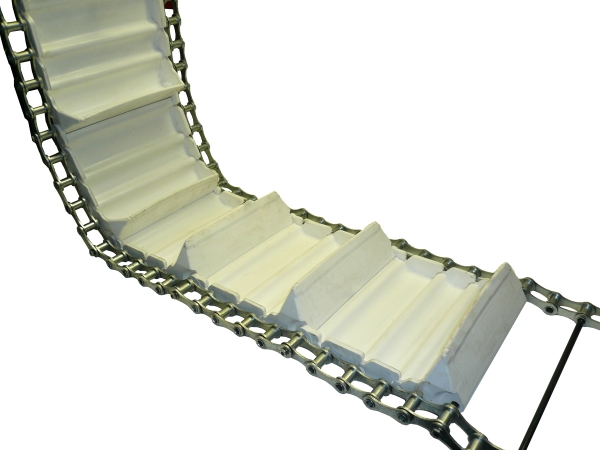

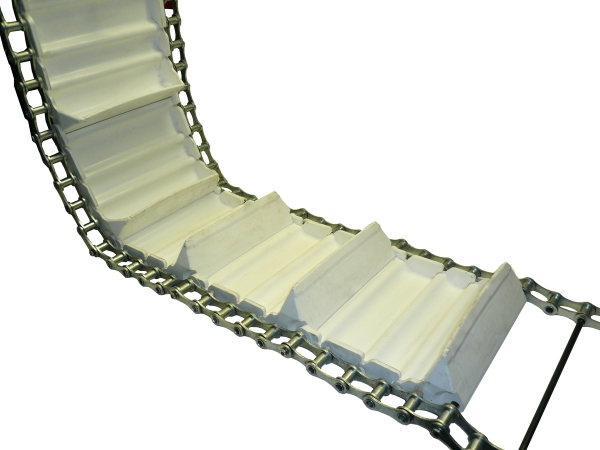

The new high capacity soft bucket conveyance system

Driven by 2 chains, ensures a greater robustness, without any maintenance. The Selecta 3 allows high- speed harvesting close to the ground.

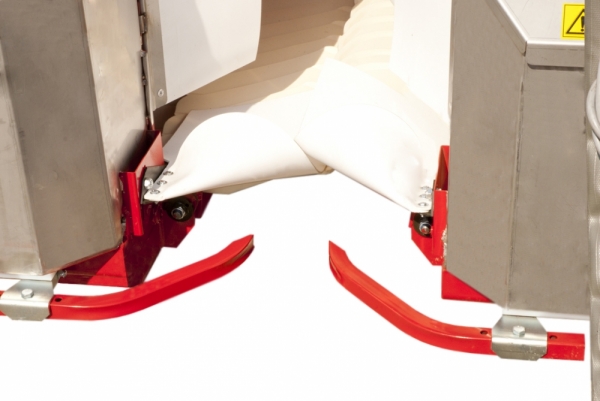

The new ÂŦARCÂŧ bent shakers

Guarantee outstanding harvesting quality, safeguarding harvested grapes and without damaging vines.

Comfort and safety

Ladder, handrail, access platform and toolbox are located on the driver side.

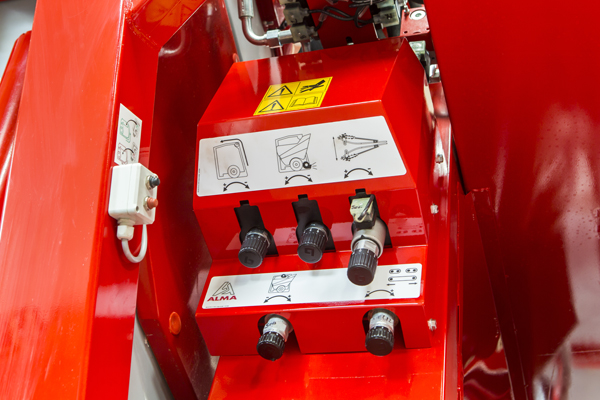

Setting comfort

In addition to the front control box, the rear instrument panel protected by its metal guard also allows manually setting all the machineâs elements : conveyors,conveyor belt, fans, shakers,etc ...

User comfort

A compact, easy-to-install metal control box.

The control handle, for driving / harvesting operations, offers the following functions : slope, levelling, guidance, start / stop shakers, pulse-controlled FWD / REV drive mechanism.

The control box includes the luminous shaking tachometer, shaking variators, stop-pick speed and drive mechanism, as well as the start / stop controls for the top and the bottom fans, the FWD / REV conveyor control, the power on indicator, the conveyor alarm buzzer and the emergency stop button.

PrÃĐcision and tranquillity

Automatic guidance with adjustable speed feelers.

Maintenance and long service life

Centralised lubrication, optionally available, allows accessing all the SÃĐlectaâs high points.

Fast hitching

Standardised 3-pin hitching system, sliding into the Road / Walk position. Remote hydraulic cylinder option controlled by the tractor.

The new ÂŦARCÂŧ bent shakers

Guarantee outstanding harvesting quality, safeguarding harvested grapes and without damaging vines.

There are 3 versions of the model :

SELECTA 3 XL ......... 2,50 m long - 30 HL

Mechanics

Hydraulic engineering system indÃĐpendent power take-off tractor( pumps integrated into reservoir ).

Motor wheels : POCLAIN 1575 cc engine size/

BUCHER 1535 cc engine size.

Power can be adjusted using control panel.

Forward and reverse operation can be adjusted using the

joystick ( on impulse ) and on the panel ( permanent).

Down-slope braking.

Deflection mini 3,50 m.

Tyres : 320/70 R20

Control panel

Easy to install thanks to its compact size.Ergonomic handle for perfect control while driving

the vehicle.

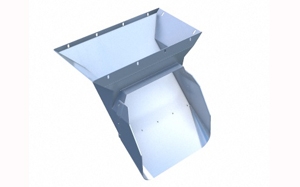

Harvesting head

Inoxidizable steel transporters : 2 high capacity noria scoops( size 320 mm ) each carried by 2 adjustable chains.

Safety transporter : forward and reverse operation of norias

with sound alarm.

Hoppers : 30 HL ( 2 x 15 HL).

ZRP walkers : 10 arc bent shakers, with positioning plate on

carrying walkers in a layer and silentblocs ( diameter 30 ).

3 position amplitude and multi-position deadheading.

Proportional adjustment and control tachometer.

Cleaning : can be regulated using control panel : 2 smaller extractors

on vertical axis and 2 extractors on hoppers at the drop of the

transversal transporters.

Air tightness : 2 flexible scale ramps, 2,50 m long and reverse

recuperators.

Dimensions : canal height 1,95 m + ÃĐlÃĐvation 0,7 m = 2,65 m.

Elevation

Elevation max. : 700 mm.Useful emptying height : 3,15 m maxi at rest.

Slant correction : 34% Plate correction : 25%

Automatic guiding

Permanent synchronisation systembetween the tractor and the harvester.

Adjustable speed : can be adjusted by

the controller positionned on the

hydraulic controls.

Comfort aspects

Ladder to the left with footbridgeTool box built into the ladder.

Guiding sensor within easy reach.

Wash basin behind on the left.

Optional

Stop-pick.Oiling centralised.

Offset cylinder road / work position on

towing.

Remote-control comfort and safety.

400 bars drive mechanism with motor

Poclain.

Sélecta 3.1

The SELECTA 3 incorporates the latest ALMA innovations: shaking, conveying, sorting, and steering. 50% less expensive than a self-propelled harvesting machine, it offers harvesting quality equivalent to a self-propelled machine with outstanding driving comfort.

The SELECTA 3.1, simple and efficient, is very competitive with all the technology necessary for a quality result.

Efficiency

- Continuous control working speed of up to 7 km/h

- Total bin capacity up to 3,000 L

- Functions well in dense vegetation

- High yield

- Crop quality

- Optimal collection around stakes

- Protection of foliage (no shearing)

Practical

- Minimum maintenance with easy access and secure to the zones to be cleaned

- Optimised for driving on the road : width 2,50 m

- Bin emptying up to 3.1 meters

- Easy headland turning with large offset angle

Cost-effective

- 50% less expensive than a self-propelled harvesting machine.

Easy to handle

- Auto-guidance in the rows

- Work on side slope of up to 34 %

- Suitable for all vineyards

Simple piloting

With the ergonomic joystick and the drive housing very compact, you can instantly set from the cab:

- The conveyor front / back

- The manual guide

- Shaking

- Tilt correction (right, left)

- The correction of plate (front, back)

- Emptying of bins

- Drawbar steering

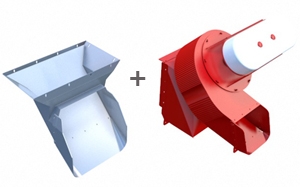

Sélecta 3.2

The SELECTA 3 incorporates the latest ALMA innovations: shaking, conveying, sorting, and steering. 50% less expensive than a self-propelled harvesting machine, it offers harvesting quality equivalent to a self-propelled machine with outstanding driving comfort.

The SELECTA 3.2, offers a good cleaning thanks to the superior ventilators. Itâs very competitive with all the technology necessary for a quality result.

Efficiency

- Continuous control working speed of up to 7 km/h

- Total bin capacity up to 3,000 L

- Functions well in dense vegetation

- High yield

- Crop quality

- Optimal collection around stakes

- Protection of foliage (no shearing)

Practical

- Minimum maintenance with easy access and secure to the zones to be cleaned

- Optimised for driving on the road : width 2,50 m

- Bin emptying up to 3.1 meters

- Easy headland turning with large offset angle

Cost-effective

- 50% less expensive than a self-propelled harvesting machine.

Easy to handle

- Auto-guidance in the rows

- Work on side slope of up to 34 %

- Suitable for all vineyards

Simple piloting

With the ergonomic joystick and the drive housing very compact, you can instantly set from the cab:

- The conveyor front / back

- The manual guide

- Shaking

- Tilt correction (right, left)

- The correction of plate (front, back)

- Emptying of bins

- Drawbar steering

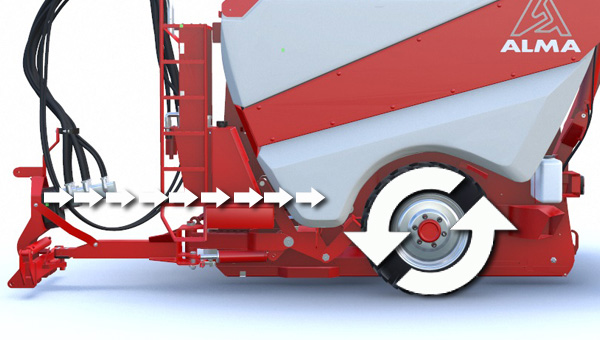

Hydrostatic transmission

This transmission immediately controls wheel movement when going up and downhill

Pump 300 bars and engine piston

The SELECTA 3.2 works on slopes with a gradient of up to 35%

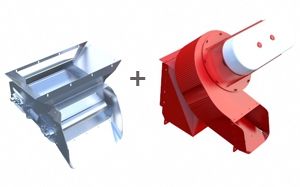

Sélecta 3.3

The SELECTA 3 incorporates the latest ALMA innovations: shaking, conveying, sorting, and steering. 50% less expensive than a self-propelled harvesting machine, it offers harvesting quality equivalent to a self-propelled machine with outstanding driving comfort.

The SELECTA 3.3 offers a very good cleaning thanks to power plant of cleaning on each of the hoppers. It differs for its side mats and its independent superior ventilators, for more speed, efficiency and regularity of the cleaning of the grape harvest.

Efficiency

- Continuous control working speed of up to 7 km/h

- Total bin capacity up to 3,000 L

- Functions well in dense vegetation

- High yield

- Unmatched crop quality

- Optimal collection around stakes

- Protection of foliage (no shearing)

Practical

- Minimum maintenance with easy access and secure to the zones to be cleaned

- Optimised for driving on the road : width 2,50 m

- Bin emptying up to 3.1 meters

- Easy headland turning with large offset angle

Cost-effective

- 50% less expensive than a self-propelled harvesting machine.

Easy to handle

- Auto-guidance in the rows

- Work on side slope of up to 34 %

- Suitable for all vineyards

Simple piloting

With the ergonomic joystick and the drive housing very compact, you can instantly set from the cab:

- The conveyor front / back

- The manual guide

- Shaking

- Tilt correction (right, left)

- The correction of plate (front, back)

- Emptying of bins

- Drawbar steering

Hydrostatic transmission

This transmission immediately controls wheel movement when going up and downhill

Pump 300 bars and engine piston

The SELECTA 3.3 works on slopes with a gradient of up to 35%

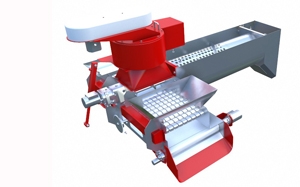

Sélecta 3.4

The SELECTA 3 incorporates the latest ALMA innovations: shaking, conveying, sorting, and steering. 50% less expensive than a self-propelled harvesting machine, it offers harvesting quality equivalent to a self-propelled machine with outstanding driving comfort.

The SELECTA 3.4, equipped with a table of sorting to separate beads, her allows a very good sorting of the grape harvest in a vineyard high yield. It allies precision in the sorting and the cleaning of the grape harvest.

Efficiency

- Continuous control working speed of up to 7 km/h

- Total bin capacity up to 3,000 L

- Functions well in dense vegetation

- High yield

- Unmatched crop quality

- Optimal collection around stakes

- Protection of foliage (no shearing)

Practical

- Minimum maintenance with easy access and secure to the zones to be cleaned

- Hydraulic raising central ventilator to facilitate the access

- Optimised for driving on the road : width 2,50 m

- Bin emptying up to 3.1 meters

- Easy headland turning with large offset angle

Cost-effective

- 50% less expensive than a self-propelled harvesting machine.

- Save a table of sorting in cellar

Sorting table

100 % of leaves are removed.

The sorting table consists of a series of feeder rollers that separate the berries, waste to be sucked up.

The adjustable screen roller allow the berries to fall into in the bins intact.

Easy to handle

- Auto-guidance in the rows

- Work on side slope of up to 34 %

- Suitable for all vineyards

Simple piloting

With the ergonomic joystick and the drive housing very compact, you can instantly set from the cab:

- The conveyor front / back

- The manual guide

- Shaking

- Tilt correction (right, left)

- The correction of plate (front, back)

- Emptying of bins

- Drawbar steering

Hydrostatic transmission

This transmission immediately controls wheel movement when going up and downhill

Pump 300 bars and engine piston

The SELECTA 3.4 works on slopes with a gradient of up to 35%

Sélecta 3.5

The SELECTA 3 incorporates the latest ALMA innovations: shaking, conveying, sorting, and steering. 50% less expensive than a self-propelled harvesting machine, it offers harvesting quality equivalent to a self-propelled machine with outstanding driving comfort.

The SELECTA 3.5, equipped with the berry lifter separator for a total abolition of the raid and the foreign body, the harvest can go straight into the vat. It associates with the table of separation, a system of unlockable berry lifter simple and strong.

Efficiency

- Continuous control working speed of up to 7 km/h

- Total bin capacity up to 3,000 L

- Functions well in dense vegetation

- High yield

- Unmatched crop quality

- Optimal collection around stakes

- Protection of foliage (no shearing)

Practical

- Minimum maintenance with easy access and secure to the zones to be cleaned

- Hydraulic raising central ventilator to facilitate the access

- Optimised for driving on the road : width 2,50 m

- Bin emptying up to 3.1 meters

- Easy headland turning with large offset angle

Cost-effective

- 50% less expensive than a self-propelled harvesting machine.

- Save a table of sorting in cellar

Berry lifter separator

· The sorting table consists of a series of feeder rollers that separate the intact berries to bring down them in trucks without passing by the berry lifter. The clusters and the foreign body are managed in the helical berry lifter for the final sorting.

· 100 % of sheets are eliminated, as well as 100 % of the foreign body

Optimum harvest quality

· 99 % of good berries in the bin

· The stems are fully rejected

- Approaching perfect harvest quality

Cost-effective

- De-stemming and sorting is done directly in the vineyard

- Eliminates storage, transport, waste processing, and cleaning of equipment in the winery

Efficiency

- Capacity of bins completely preserved

- Working speed identical to a standard harvesting head

- Lightest on-board destemming and sorting system on the market

- the center of gravity is protected

Easy to handle

- Auto-guidance in the rows

- Work on side slope of up to 34 %

- Suitable for all vineyards

Simple piloting

With the ergonomic joystick and the drive housing very compact, you can instantly set from the cab:

- The conveyor front / back

- The manual guide

- Shaking

- Tilt correction (right, left)

- The correction of plate (front, back)

- Emptying of bins

- Drawbar steering

Hydrostatic transmission

This transmission immediately controls wheel movement when going up and downhill

Pump 300 bars and engine piston

The SELECTA 3.5 works on slopes with a gradient of up to 35%